Empty running: It’s impact on transport and the environment

Empty running is a critical concern with logistics professionals, impacting both increasing operational costs and profitability, while also hindering the logistics industry’s broader goal of minimising its carbon footprint. In the following article, we’ll explore the reasons behind the substantial issue of empty running within the industry and explore potential measures to mitigate its impact.

What does ‘empty running’ mean?

Empty running (also referred to as ‘Empty Miles’) refers to any journey that is carried out with an empty vehicle or empty trailer, and without earning any income or financial gain. Although unavoidable at times, empty running can be very costly to hauliers and the environment. With the rising cost of fuel, combined with growing competition and enhanced customer expectations, margins are tighter than ever. Income opportunities are fiercely contested, meaning that making the most out of every mile travelled is essential for success.

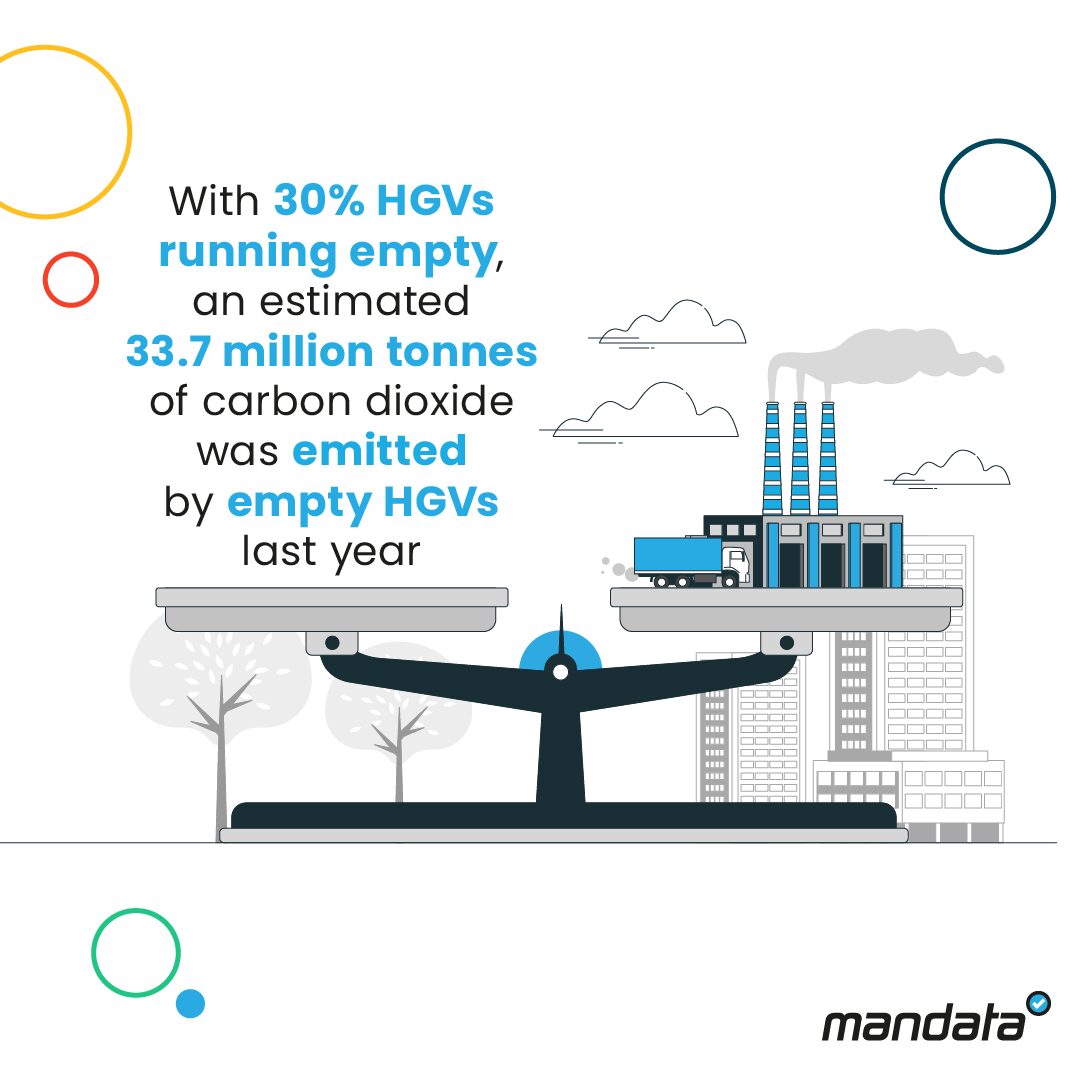

Empty running is not a new problem in haulage, in fact it has always been a very prominent issue. It is estimated that 30% of HGVs are running empty in the UK alone, and last year it’s estimated that 3.6 billion miles were travelled in the UK empty. Needless to say, that is an extremely high number, and one which is unsustainable for hauliers.

The significant consequences of empty running

Running empty has severe cost implications to haulage businesses as wasting resources is a luxury that no haulier can afford in these tough times.

When vehicles are travelling without a full load to stabilise them, it can result in increased wear and tear on various vehicle components, including tyres, suspension systems, and braking systems. This extra strain on components can lead to accelerated deterioration, demanding more frequent maintenance and costly replacements.

Running a high number of dead miles can also hinder the haulier’s customer service. Running vehicles empty consumes valuable time and resources that could be used to fulfil existing customer orders promptly and efficiently. Transport is an industry built on service reputation, and if tarnished it could damage customer retention and future business.

How is empty running contributing towards the environmental crisis?

There has been an enormous shift in focus for the haulage business in recent times towards decarbonisation initiatives (such as Net Zero), and the imperative to implement more eco-conscious processes. Empty running is an area within transport identified as a large contributor to the industry’s carbon footprint. It is estimated that the transport industry contributes around 34% of the UK’s greenhouse gases, so whatever can be done to reduce this must be explored.

The transport sector was responsible for 112.5 million tonnes of CO2 in 2022. If 30% of HGVs ran empty in this time, it means that around 33.7 million tonnes of carbon dioxide were emitted by empty HGVs last year. These numbers show why this issue is being so highly prioritised.

How can technology help reduce empty running?

Using industry standard software solutions such as transport management software (TMS), can greatly help businesses to become more efficient with their daily job planning. By utilising industry best practice, this should help to reduce empty running within their operations.

Here are a few ways TMS software features can facilitate reducing empty mileage:

- Optimise route planning: Using robust planning functionality, planners can identify the most efficient routes, reducing unnecessary and empty mileage. It avoids obstacles like low bridges to prevent diversions and further dead miles.

- Evaluate vehicle sizes and capacity: Technology can help identify and recommend where using smaller vehicles may be more appropriate to certain jobs, helping to improve capacity utilisation and simultaneously reducing emissions.

- Improve driver communication: Utilising driver communication apps, such as the Mandata Manifests app allows operators to directly send planned routes directly to drivers, along with the directions through the sat-nav integrations, ensuring they follow optimised routing and avoid extra mileage.

- Manage drivers’ hours more efficiently: With limited hours in the day for drivers to work, ensuring their driving hours are capitalised in the most efficient way is essential. With tacho analysis data, linked up to a TMS, drivers’ hours can be planned accordingly and not wasted on empty running.

- Utilise freight exchange platforms: Freight exchange platforms, such as Returnloads, enable transport companies to post available jobs and vehicles seeking work. This allows businesses to find available work in their area, turning empty runs into revenue-generating opportunities.

What else could help to reduce empty miles?

- Enhanced collaboration: Transport businesses can collaborate to reduce empty running by sharing resources and work opportunities.

- Transport planners training: Properly training staff in industry best practices is crucial for efficient planning and reduced empty mileage.

- Established return load agreements: Establishing agreements and contractual work with other companies for return loads can help reduce empty running. These agreements ensure that a vehicle will carry cargo for two or more companies, with each taking responsibility for a portion of the journey.

- Utilised industry initiatives: Staying informed about environmental initiatives, collaboration efforts, and regulatory updates through industry forums and events. The RHA’s Net Zero forum is a great example of this.

Addressing the issue of empty running in the UK’s haulage industry is crucial for both business efficiency and environmental sustainability. By adopting innovative technologies, fostering collaboration, and staying informed about industry initiatives, the problem can be significantly eased.

Read more: The Transport Operator’s TMS Buyer’s Guide